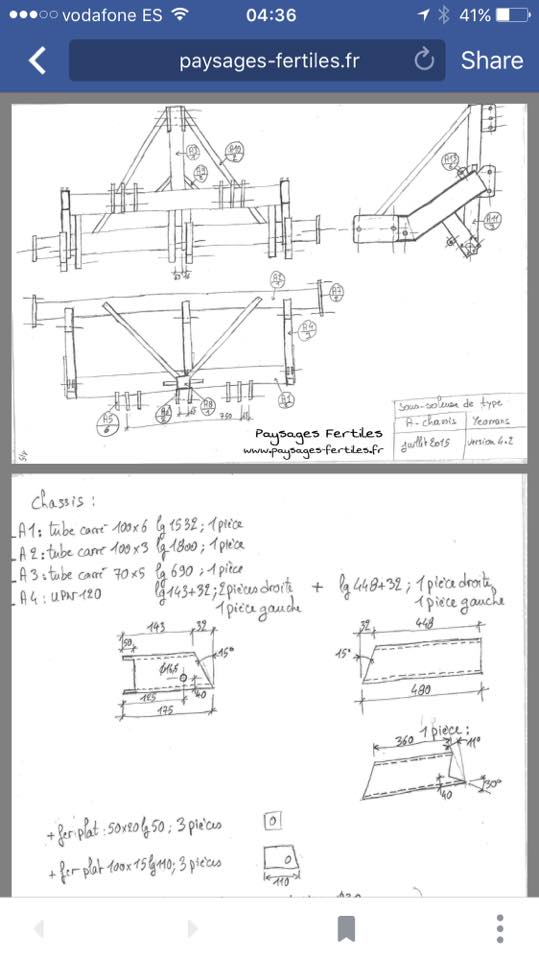

Over the last few years Franck Chevallier (France) has developed a open source (OS) subsoiler which is designed to be able to be built by local metal workers using readily available materials.

In 2016 Regrarians’ Darren J. Doherty instigated the formation of a working group to develop formal CAD plans to support Franck’s effort and to further develop the #KeylineSuperPlow concept we’ve been working on for over 20 years but in earnest since 2006/7. (Refer to the #KeylineSuperPlow History article for the full story)

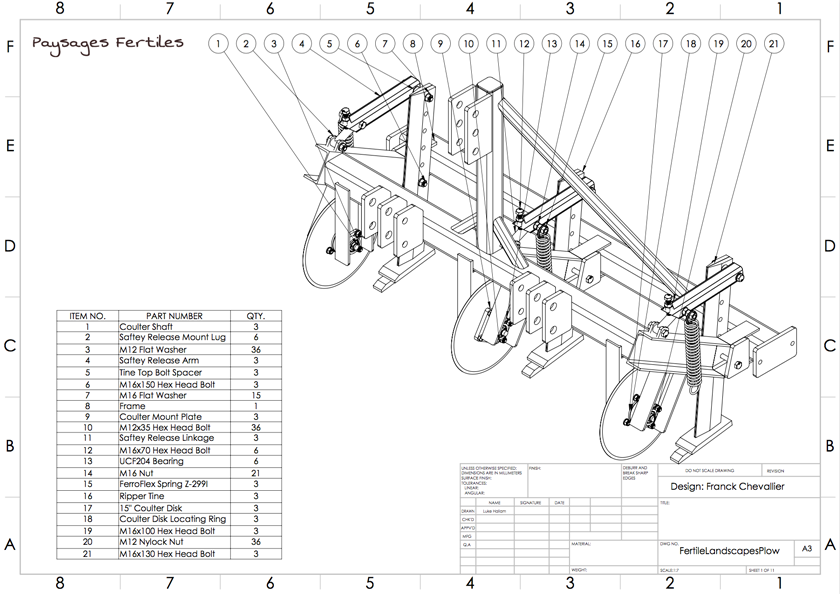

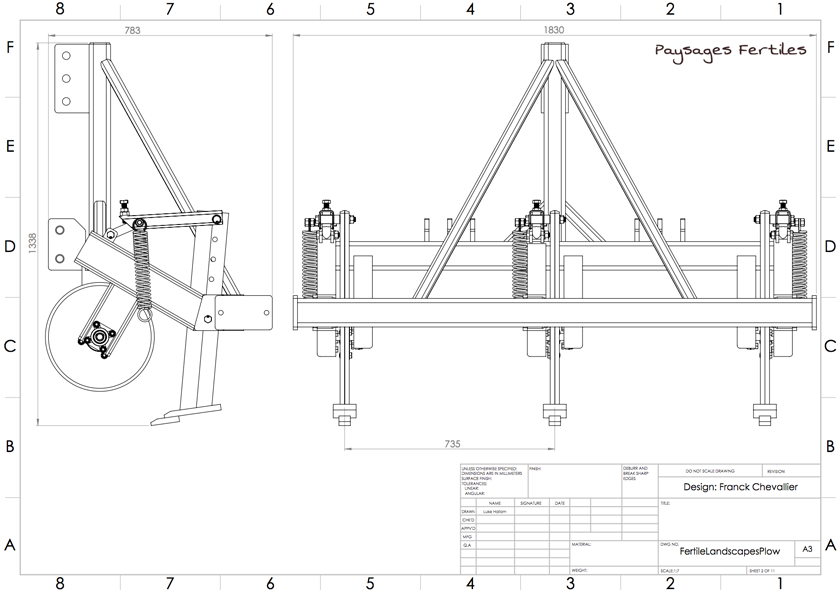

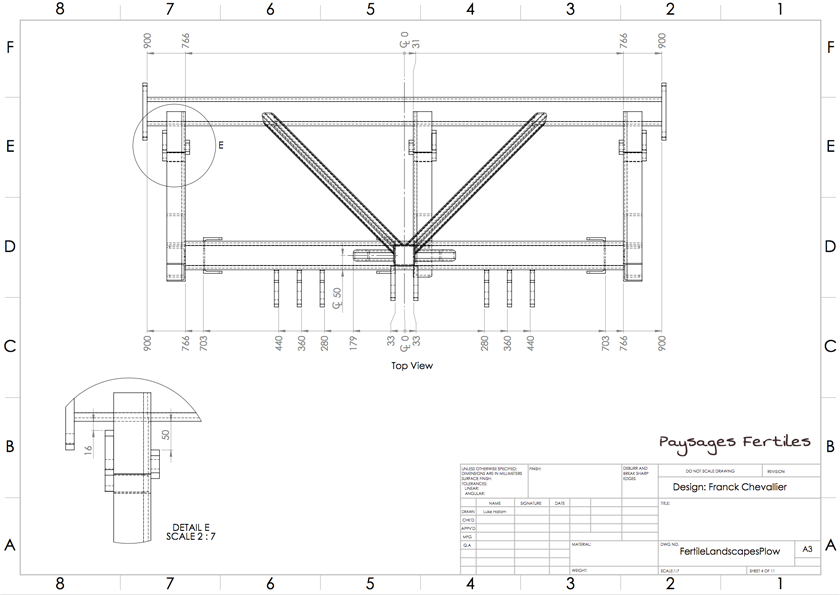

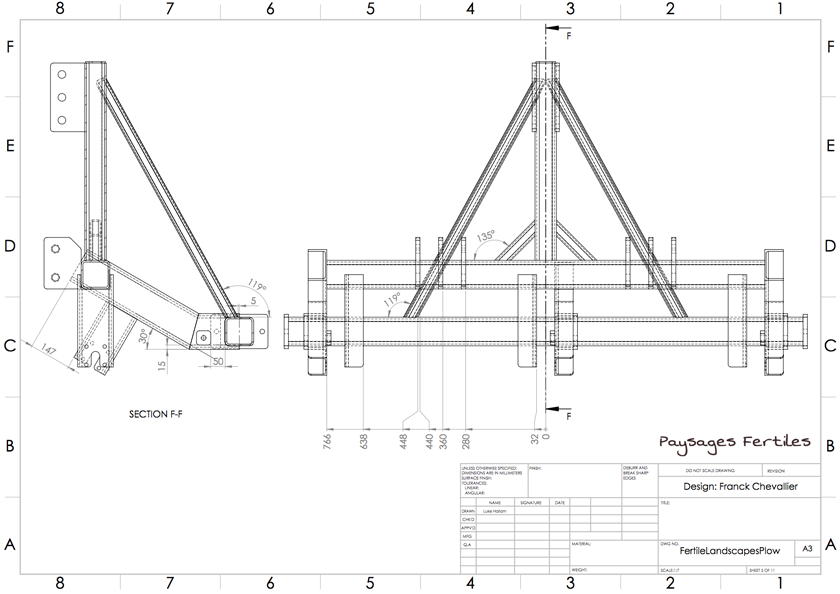

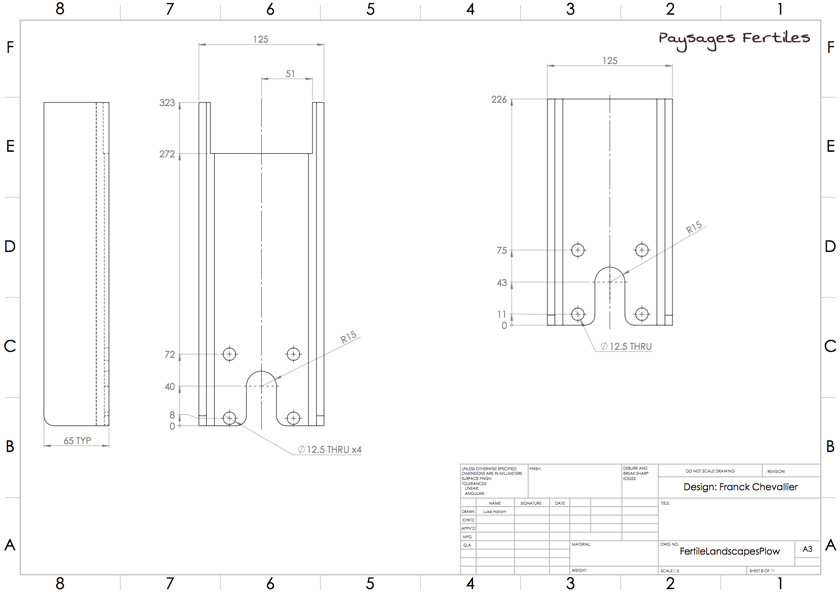

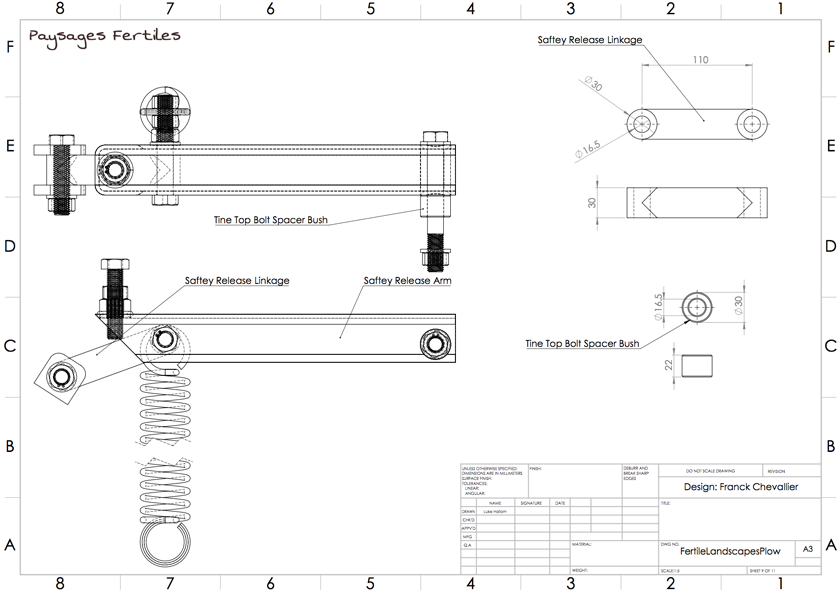

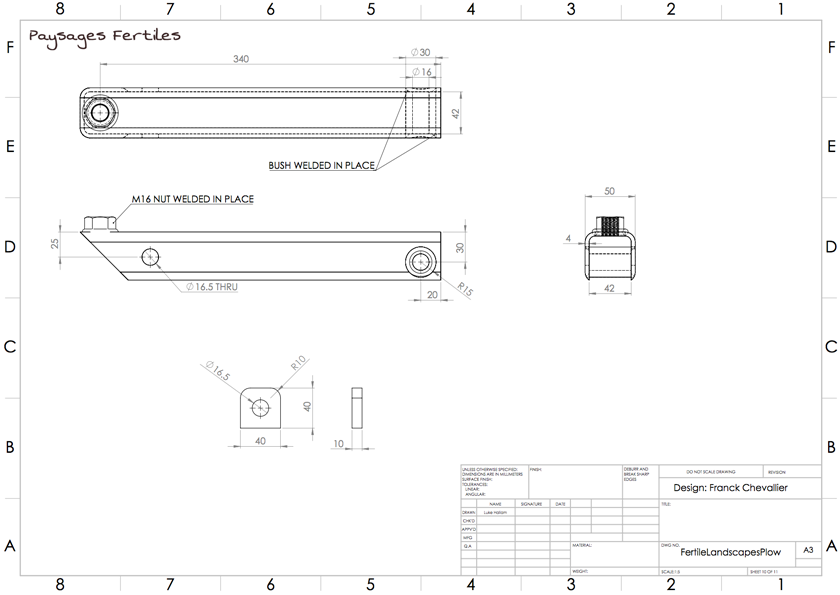

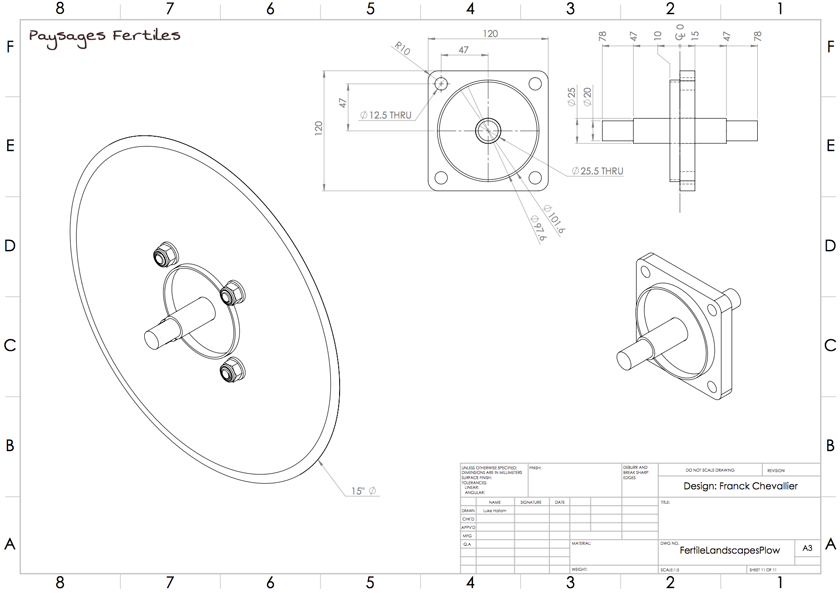

Luke Hallam (South Australia) has came to the fore with the development of many CAD concept models and these are manifested in this set of working drawings. Luke and Franck have done a great service in doing this fantastic and unpaid work!

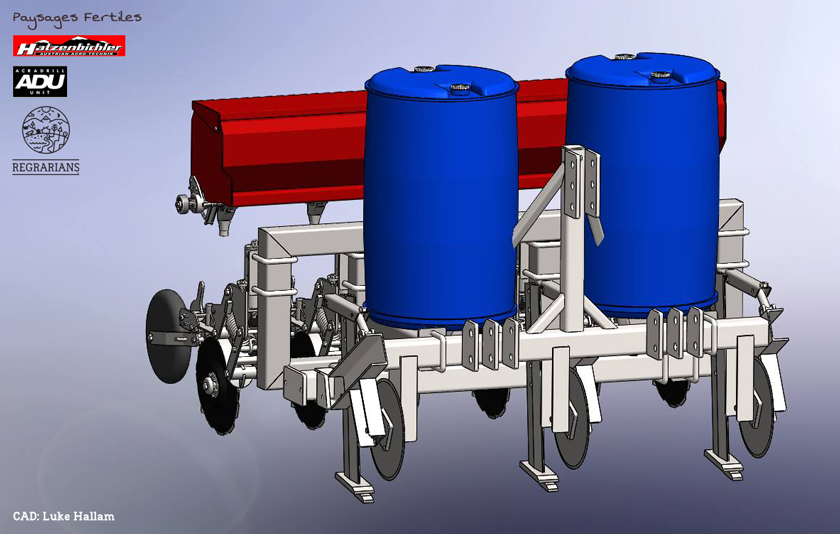

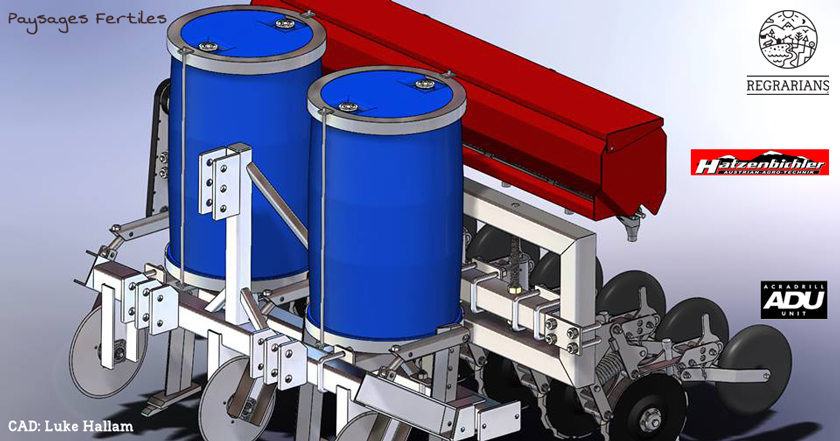

McIvor Farm Foods Jason Hagan has also done a great job in his development of the #KeylineSuperPlowM3 and his work (in collaboration with Regrarians) has been instrumental in the development of this Fertile Landscapes prototype, especially when it comes to his adding a gang of 2nd hand Acra no-till disc drill seeding units to the Regrarians Keyline Plow (with a fluted roller type Hatzenbichler seedbox). This proved to be a real breakthrough. Planting seeds either side of the Keyline Plow shanks’ rip line give the germinating plants the ‘jump’ on other plants due to the ‘kill-zone’ either side of the rip line.

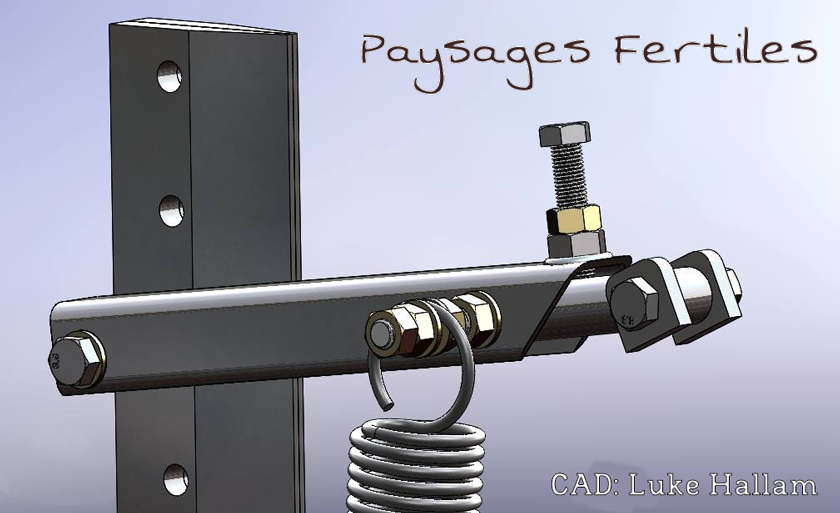

The best feature of Franck’s design is the very unique and effective shank break-out mechanism. Its superior to any other system commercially available, with the exception of the very expensive hydraulic break out systems.

The next step is to have the #KeylineSuperPlow concept go through a similar CAD process and this is now underway.

More recently Luke Hallam and Darren J. Doherty have been working on plans for an OS no-till drill that can also be built locally.One of our primary design objectives is to design implements that can be built by local metal workers in the countries which could benefit from no-till machinery.

Following are a series of photos and diagrams to help better understand our objectives and the journey so far:

Franck Chevallier turning on the tap from the biofertiliser tank on one of his ‘Paysages Fertiles’ (‘Fertile Landscapes’ in English) machines

One of Franck’s many homemade innovations — a home made seedbox driven by a bicycle wheel. Seeding rates can be adjusted by changing gears!

Another view of the above machine

Detail of some of the seeder tubes that Franck has running behind this gang of fluted coulters

Franck showing Regrarians’ Darren J. Doherty how his ingenious subsoiler breakout system works on this basic subsoiler model

This photo shows the single shank subsoiler model engaged

This is another photo of the same single shank machine, this time showing the disengagement of the ingeneous breakout system that Franck has devised. To re-engage you simply reverse until its engaged, lift to avoid the obstactle, drop the plow in again and keep ploughing.

An original hand drawing Franck supplied us when we formed the OS Fertile Landscapes SuperPlow working group

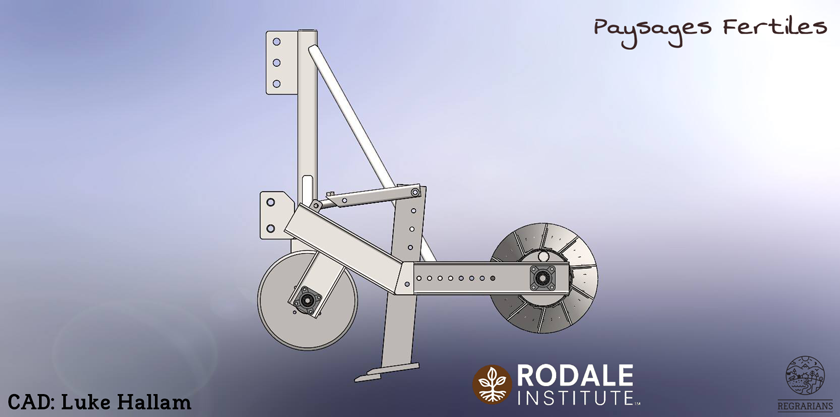

OS Fertile Landscapes SuperPlow working group’s Luke Hallam CAD render of Franck’s shank break out system

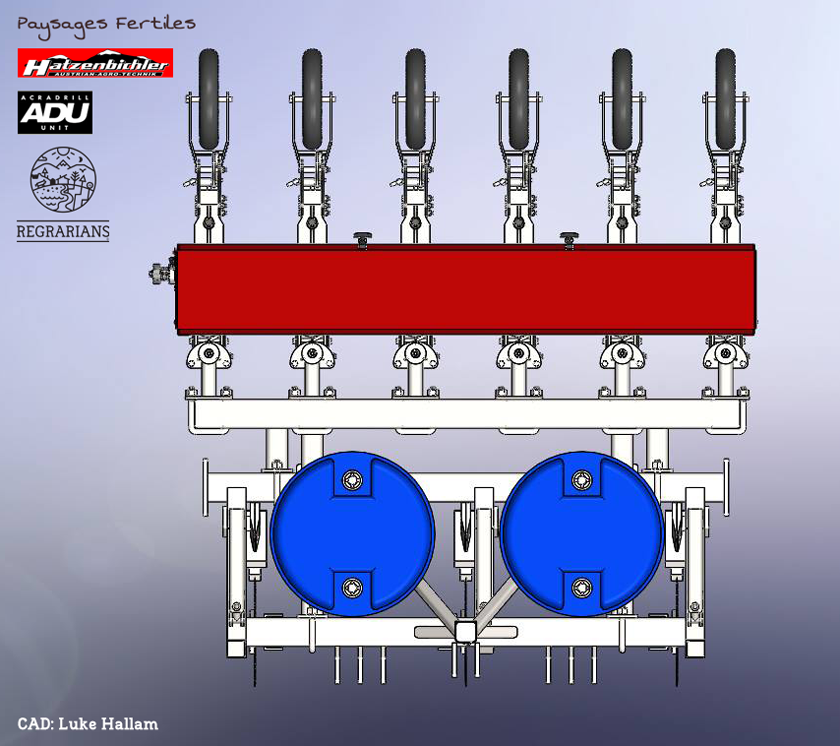

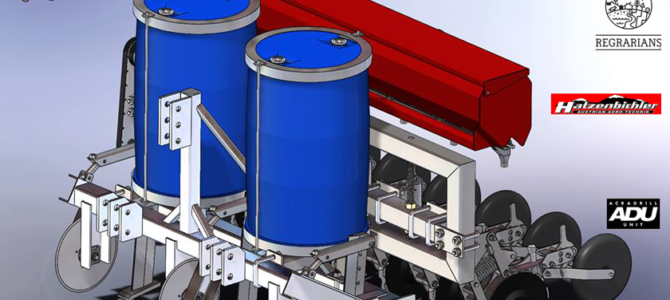

The full working CAD drawings (by Luke Hallam) of the Fertile Landscape Plow

The Rodale Institute’s Crimper Roller has been an inspiring addition to the organic no-till movement — it provides the possibility to grow commercial organic cereal and grain legume crops without herbicide and cultivation.

Our colleagues in Guadalajara (Jalisco) Mexico at Alaska Hitch built a wide crimper roller for a client of Regrarians and MasHumus

The same completed crimper roller by Alaska Hitch.

Inspired by the Rodale crimper roller design we integrated this design as the roller on the Fertile Landscapes Plow (sectional elevation)

Plan view

3D view

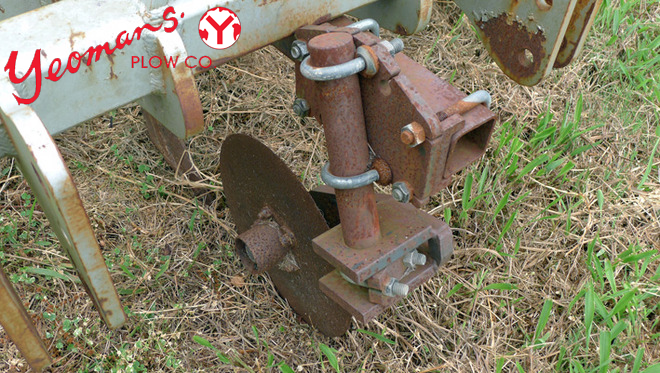

In the autumn of 2016 McIvor Farm Foods Jason Hagan bought a gang of 2nd hand Acra no-till disc drills to make the #KeylineSuperPlowMk3. This was an inspired move as previously we had a lot of seed wastage on the 2 previous prototypes of the #KeylineSuperPlow, starting with our work with Taranaki Farm‘s Ben Falloon in 2010. Mk1 had the same Hatzenbichler seedbox as Mk3 mounted onto a Yeomans Plow Co. SB3 plow frame (same model as above). Seed was dropped into the Yeomans Keyline Plow rip lines. This proved to be very hit and miss. Mk2 had Jason and I attach a row of 6 of the new Yeomans Plow Co. ‘Sticky Legs’ with a ‘Baker’ or ‘T’ boot point attached. This was a big improvement over Mk1 better however without a coulter there was significant trash build up.

Close up of the Jason Hagans’ tool bar for attaching the gang of Acra no-till disc drills on the #KeylineSuperPlowMk3

Another view of the #KeylineSuperPlowMk3 showing how Jason fixed the disc drill tool bar to the Yeomans Plow Co. SB3 frame

Despite a significant litter layer the #KeylineSuperPlowMk3 that McIvor Farm Foods’ Jason Hagan built was able to sow a mixed species cover crop with ease.

This photo shows the strategic placement of the Acra no-till disc drills either side of the Yeomans Plow Co. plow rip lines.

A few weeks later and the oat-based (Avena sativa) cover crop has established in competition with an annual/perennial grasses and forbs. The area either side of the Yeomans Plow Co. rip line has a delayed rate of germination — this helps the sowed cover crop get the ‘jump’ on the other species that are germinating after natural rainfall — this breakthrough confirmed what #PastureCropping co-originator Colin Seis suggested to both Jason and I the year before at a local Pasture Cropping field day.

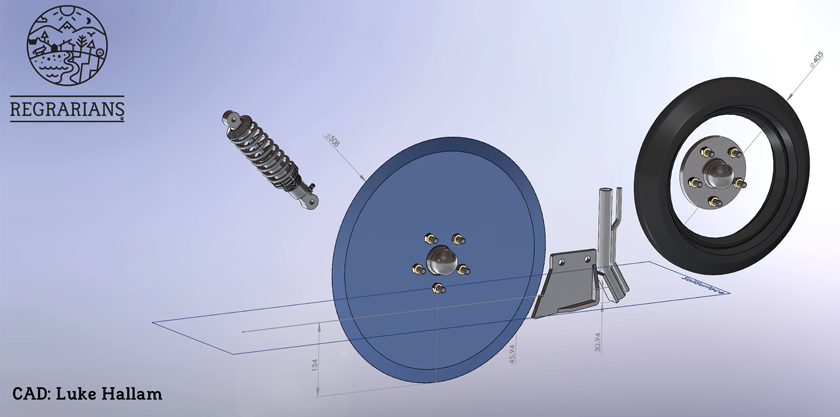

With the next version of both the Keyline Super Plow (Mk4) and the OS Fertile Landscapes Plow, Luke Hallam and I devised this new tool bar design to fit a gang of no-till disc drills (in this case a gang of Acras). This design will allow more flexibility in placing the drills according to the depth of the subsoilers and the relative width of the soil surface disturbance caused in different soil conditions.

Another addition which follows from Darren J. Doherty’s original concept is the placement of a liquids tank — for biofertiliser, microbial mixes etc. This could be a commercial tank or re-purposed tanks as shown below in the next 3 images.

Liquids could be injected at different zones or on the surface. We’ve played with using 12V pumps in the past to deliver the liquids at different rates.

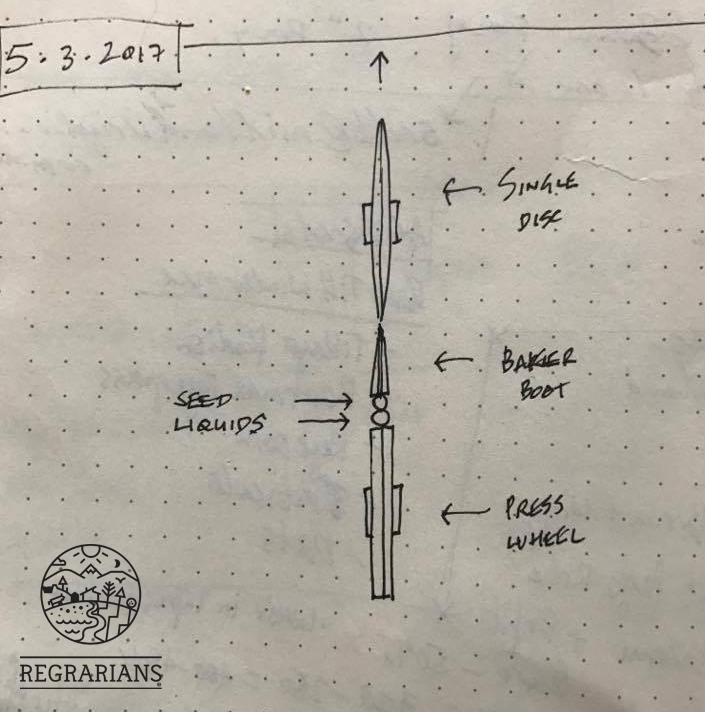

Not every producer can afford excellent no-till drills such as Acra produces. With that we’re now designing a tyne based no-till system that can be built by local steel fabricators using commonly available parts. This plan drawing addresses the primary functions and placement.

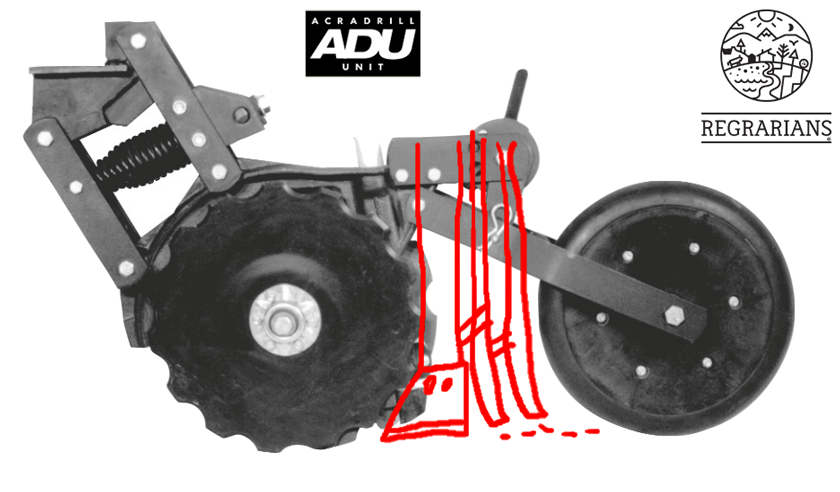

The Acra ‘ADU’ model no-till disc drills gave us the inspiration for this locally-built design. The issue with building a similar unit is the availability of this kind of sealed bearings. The shaft angles are also another matter. This kind of parallellogram design has been around for many years with each manufacturer making making their own changes to do the same job (more or less). Darren’s concept was to have a ‘Baker’ or ‘T’ boot installed with 2-3 or more seed and liquid application tubes placed immediately before a single (ideally scalloped) disc and a solid press wheel behind.

The Yeomans Plow Co. have for a long time used commonly available car/light truck hubs for many of its designs — this is extremely practical and intended by the Yeomans Plow Co. to allow users of their implements to repair and replace hubs and parts locally

Luke Hallam then produced this concept drawing of prototype no till tyne drill. Recycled rear motorcycle shock absorber’s are commonly available and our concept is to use these as the compression spring for the yet to be designed parallelogram mechanism. The Baker boot design is chosen because of its simplicity and efficacy. It can be easily build using readily available steel plate or materials such as flattened leaf springs.

Hello all,

The superplow breakout design is inspired! I am just finishing Geoff Lawton’s online permaculture course and hope to learn and apply keyline techniques in the Sierra foothills.

I would like to design and build a mid mount for my old Unimog 406 tractor to attach Yeomans type subsoiler shanks like Franck’s design.

My sketch below shows the general design with the plow both raised and lowered using 22″ Yeomans shanks. It took some time to get the linkage worked out to get the right depth, clear the ground when transporting, avoid contacting the undercarriage of the Mog and the front wheels. The location of the hinge point is critical.

I have yet to figure out how to make the breakout work. In addition, my design will need some kind breakout at full extension to prevent overstressing the hydraulic cylinders when hitting a big rock. Maybe a shear pin at the bottom end of the cylinder or some modification of Franck’s design I have yet to grasp.

https://photos.google.com/photo/AF1QipPG1-MbeTRbdpvuLYsqcx9C8bX2w1JXR811Fdje

I am building this from scraps, mainly 3/4″ thick x 6″ wide by 7′ long used up snow plow wear plates and 4×4 square tube.

To mark contours I will be placing a class II cross line laser at my eye level at a starting point and walking to the end point placing flags fifty feet apart or so while checking that I am on the beam. When running the plow I will position the laser at eye level when I am in the cab and steer by observing both the flags and the laser . By keeping my eye height slightly below the laser and periodically raising it to see the flash when on the beam I hope to closely control the elevation by steering.

Although a 22″ shank is shown, I expect to make 8″, 12″ & 16″ shanks because I can’t see a way to adjust the depth in this design. The mid mount will cut the effects of pitching in half and might eliminate the need for depth wheels. I am assuming heavy wall 4″ square tube is adequate for the toolbar. I don’t have a plan for coulters, I hope that is not a fatal flaw. I could possibly front mount coulters about 6 feet ahead of the subsoiler.

I don’t plan on plowing slopes over 30%. The Unimog can safely traverse fairly steep side slopes and its big tractor flotation tires are a big asset. Plus, it and my scrap pile is all I have:-)

Please critique my design.

Thanks for the inspiration!

Paul Miller

Central California Sierra Foothills, 40ºN, 3000′ elevation, Sites clay/loam deep well drained soil, mixed forest, mediterranean climate, 60″ annual rainfall with 6″ in 24 hours occasionally. 15-40% slopes.