1994/95

Our dear friends Nada & Tony Smark (then of Woodbrook Farm) bought us our first Yeomans Keyline Plow in return for us designing & developing their first vineyard & forest (which was a Keyline vineyard & forest – see picture below!).

What is a ‘Regrarians Keyline Superplow’?

History

Since we Nada & Tony first bought this Keyline plow in the mid 90’s we’ve been actively tacking on all kinds of other implements to make this plow as multifunctional as possible and ‘stretch’ the diesel used to fuel pull it.

1995/96

Brett Davis & Neil Meadows (then of ‘Silviculture Victoria‘) were the first to have a crack, mounting a 1m wide rotary cultivator/hoe on behind allowing us to deep rip and mechanically cultivate the grass sod, eliminating the use of herbicide, for forestry and vineyard ground preparation.

We carried on with this combination for many years and local farm forestry contractor Dave Griffiths (of Geometree) continues to use this setup today.

The came the DOJO (a neologism of DOherty & JOnes after Darren’s step father Joe Jones) iteration which put a set of 26″ discs on behind the rotary hoe allowing us to deep rip, cultivate and mound in one pass. Many people copied this concept and literally tens of millions of trees in forest plantations have been established using our DOJO concept. Around this fertile time Darren started imagining and concept planning ways to plant trees with the DOJO, water them and even put tree guards on…One day perhaps!

1998/99

Dave Griffiths of Geometree who was our forestry contractor at the time, had Watson Bedforming Systems in Geelong convert our new 1.5m Celli Rotary Cultivator into a bedformer.

This mounder did an amazing job and upped the ante with regards ground preparation for the mixed species forestry, tree crop & vineyard systems we were establishing en masse at the time.

2006/07

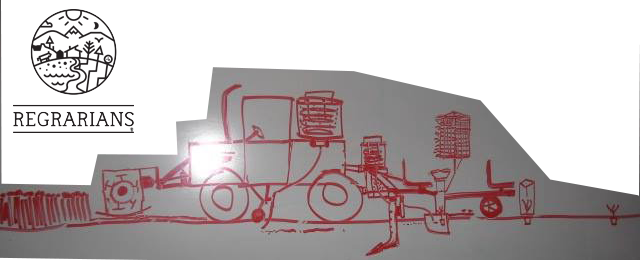

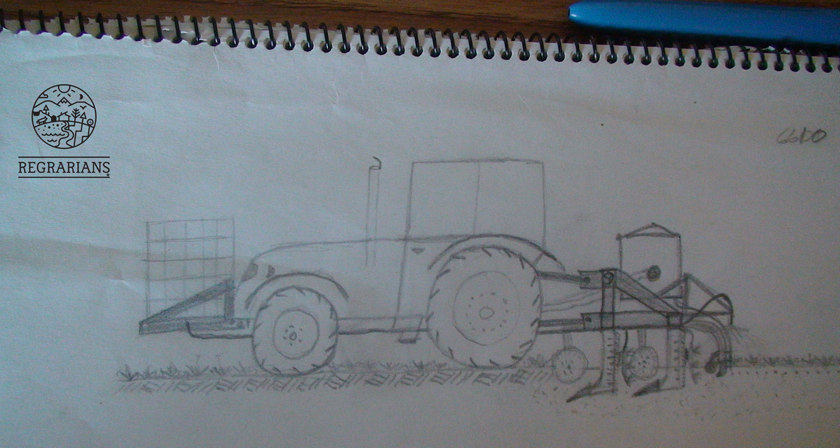

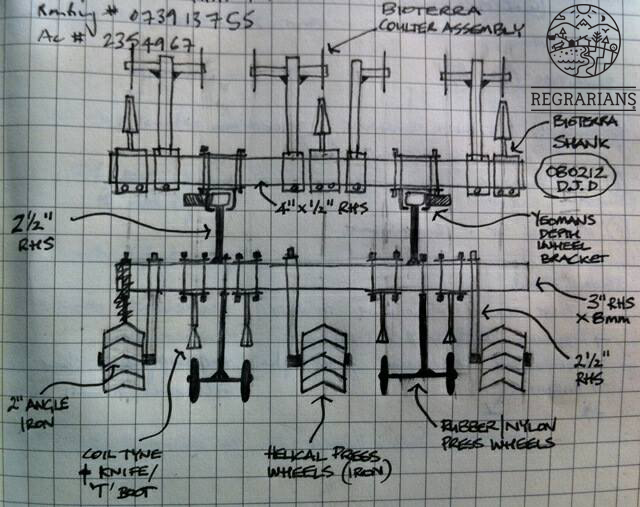

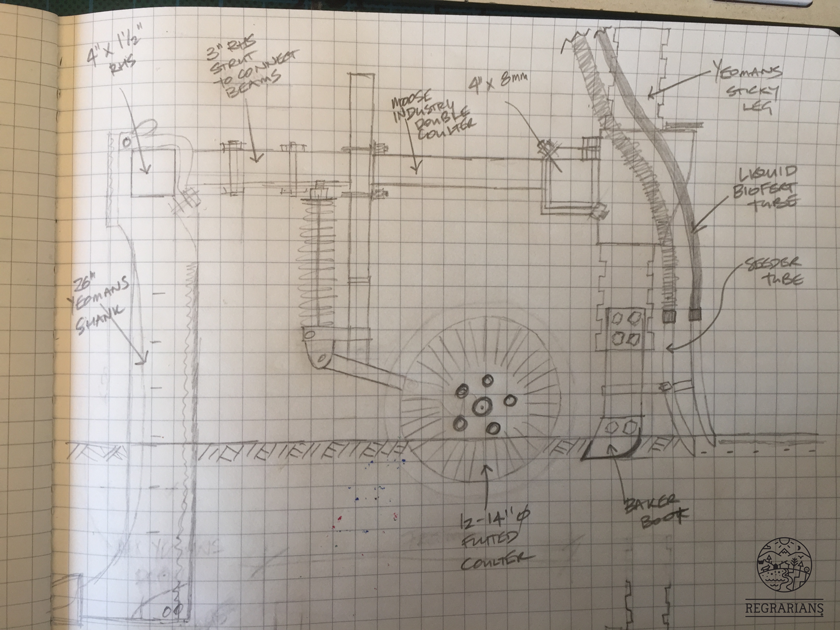

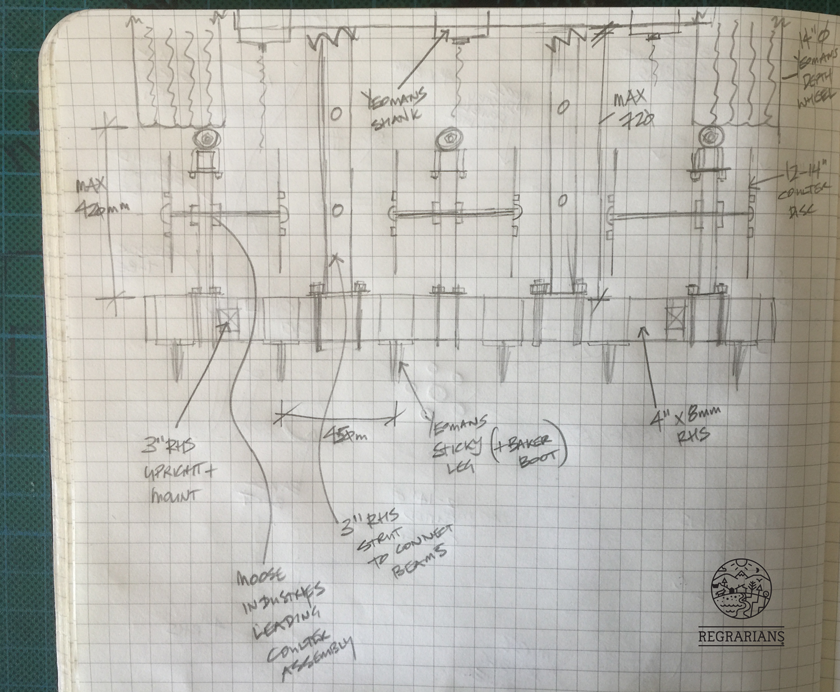

Then it wasn’t until our 2007 World Tour and the Keyline Design Course at Abe Collins’ ‘Cimmaron Farm’ in Vermont (USA) that in a chat with Ethan Roland I drew on the whiteboard my ideal Keyline Superplow concept (see below) — this was more for tree planting than for multi-species pasture cropping, no-kill cropping or cover cropping. I had drawn similar concepts in the 1990’s when we were doing a lot of tree establishment work and I was looking to save energy and time.

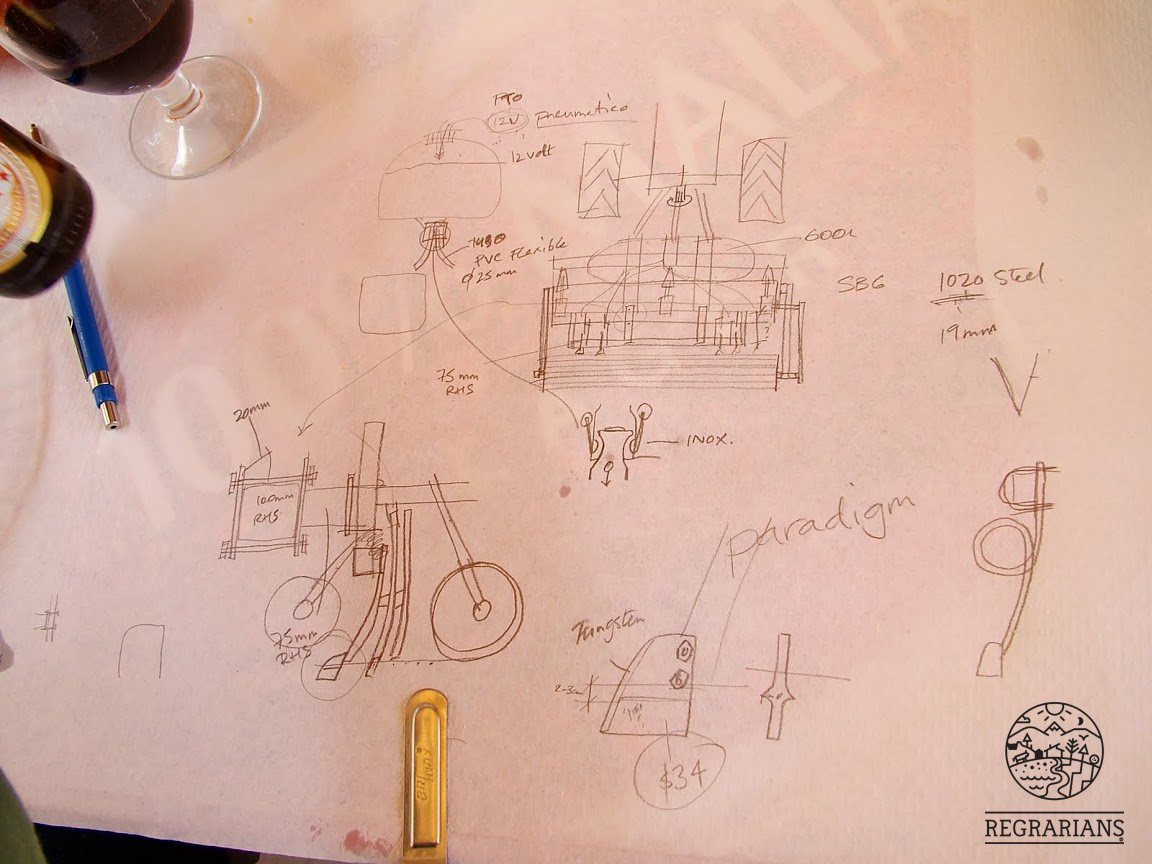

Following this and over time I’ve been drawing all manner of concepts (see below)

2008

I talked about this a bit with people and then Taranaki Farm’s Ben Falloon came back to his family farm in 2008 and I was spending a lot of time there helping him and his father Stan Falloon start the process of regenerating the farm. Ben became aware of my concepts and then went on to make the 1st prototype Keyline SuperPlow in the world.

2009

It worked really well and since then organisations such as LineaClave in Spain & others in Latin America have taken our concept on with great gusto building their own variations on our concept.

The big thing for us was talking with legendary Regenerative Agriculture pioneer and Pasture Cropping co-originator Colin Seis at his ‘Winona’ farm in NSW in 2009 when we were up at Milkwood Farm teaching a Keyline Farming Course. Colin suggested that:

“…if I used the Keyline SuperPlow in Pasture Cropping then it would probably double the rate of soil formation…”

2012

This comment got Darren thinking about making a Keyline SuperPlow work for Pasture Cropping and No-Kill Cropping (as developed by Bruce Maynard) systems on small-medium scale production systems with a view to having larger scale producers mimic this implement to further increase both soil formation and profitability: key Regrarians goals. Colin also suggested to us that placing the seed on either side of the Yeomans KeylinePlow rip lines to take advantage of the retardation of growth of existing or emerging vegetation within that zone. My concepts at that stage were to fit a gang of Primary Sales no-till sprung tynes (with baker/’T’ boots)

2015

In 2015 we started to think about how we could get this to work — especially as we looked to strategise with our clients how to manage the ‘intensive agriculture’ planning issue. Working with our friend and client McIvor Farm Foods Jason Hagan, he purchased the same 6 run Hatzenbichler seedbox as the Falloon’s had used at Taranaki Farm and Mk1 — this was also mounted onto Regrarians’ Yeomans Plow Co. SB3 plow frame. We looked at using Primary Sales no till kit however we were concerned about height adjustment so Regrarians purchased 6 of the new height adjustable Yeomans Plow Co. ‘Sticky Legs’ and attached a ‘Baker’ or ‘T’ boot point to each leg. This was a big improvement over Mk1 better however without a coulter there was significant trash build up.

When we looked at the cost of adding a Moose Industries coulter in front of Sticky Legs it became costly. By that time the sowing season had ended we put this version to bed and looked to next season to solve the problem.

2016

While we were overseas on the #REX2016WorldTour, Jason got to work on #KeylineSuperPlowM3 and his work (in collaboration with Regrarians) has been instrumental in the development of the Open Source (OS) Fertile Landscapes prototype, especially when it comes to his adding a gang of 6 second hand Acra no-till disc drills to the Regrarians Keyline Plow (with the same fluted roller-type Hatzenbichler seedbox of Mk1 and Mk2). This proved to be a real breakthrough in not only sowing seeds at the right depth, but also working well with heavy residual dry matter.

Close up of the Jason Hagans’ tool bar for attaching the gang of Acra no-till disc drills on the #KeylineSuperPlowMk3

Another view of the #KeylineSuperPlowMk3 showing how Jason fixed the disc drill tool bar to the Yeomans Plow Co. SB3 frame

Despite a significant litter layer the #KeylineSuperPlowMk3 that McIvor Farm Foods’ Jason Hagan built was able to sow a mixed species cover crop with ease.

This photo (May 2016) shows the strategic placement of the Acra no-till disc drills either side of the Yeomans Plow Co. plow rip lines.

A few weeks later (May 2016) and the oat-based (Avena sativa) cover crop has established in competition with an annual/perennial grasses and forbs. The area either side of the Yeomans Plow Co. rip line has a delayed rate of germination — this helps the sowed cover crop get the ‘jump’ on the other species that are germinating after natural rainfall — this breakthrough confirmed what #PastureCropping co-originator Colin Seis suggested to both Jason and I the year before at a local Pasture Cropping field day.

By July 2016 the crop had come away very well and we ably competing with the other species in the pasture that had emerged.

Now by August 2016 and the crop has completely dominated the landscape into which it was sown and provides an excellent forage to the Hagan’s pastured pigs, cattle and sheep.

2017

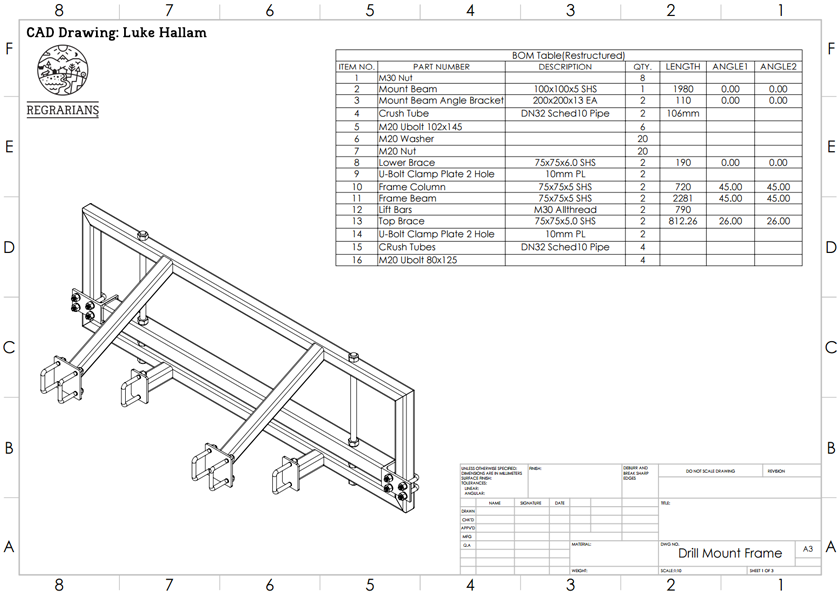

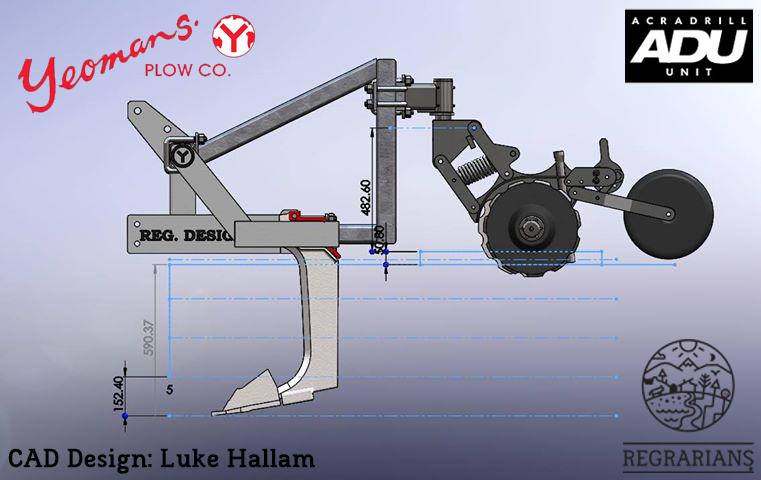

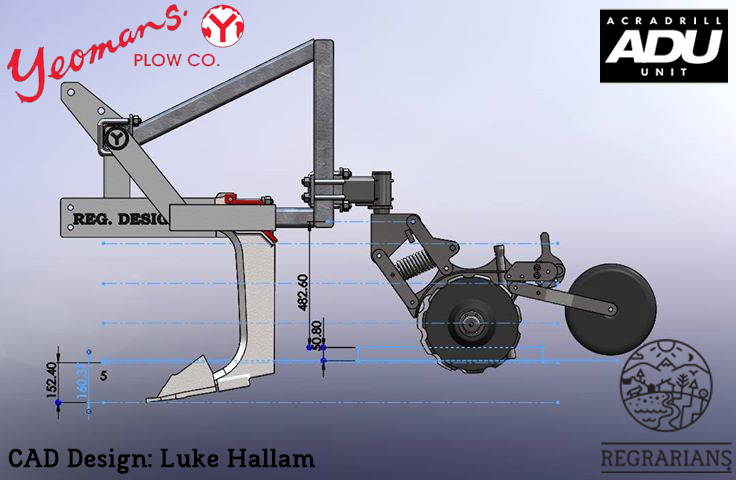

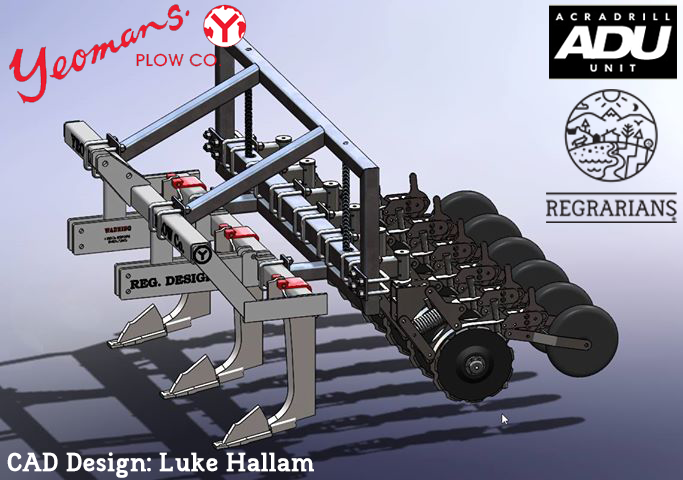

Now that we’re satisfied with this MK3 version of the #KeylineSuperPlow we’ve committed to completing CAD designs of some refinements. Here our friend and colleague Luke Hallam has used SolidWorks 3D CAD software to build an improved toolbar for the gang of double disc openers. Jason’s original design only provided vertical adjustment of the individual openers. I wanted to have horizontal adjustment as well and so Luke and I came up with the following design which we’re now ready to build.

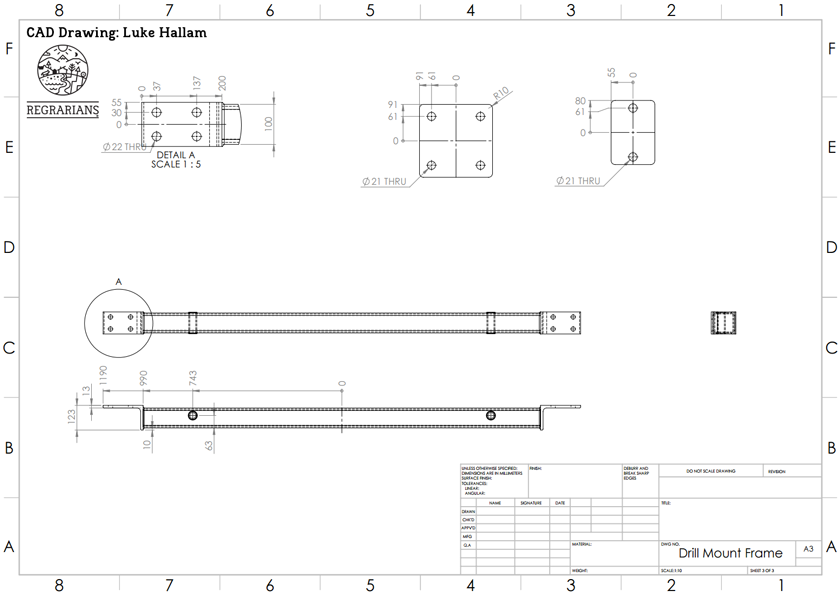

Luke has also created a set of working plans to make the frame onto which the seedbox and double disc units are mounted — this then mounts onto the Yeomans SB series toolbar/frame:

Here in Australia we’re looking to use the South Australian-made John Shearer Double Disc Opener (between AUD$1100-$1500/each) — its a beautifully engineered impliment and we look forward to giving these a run:

The Future?

Other ideas that I have are to add tanks for liquids and palletised solids injection, a small seedbox (either air seeder or fluted roller), other kinds of tyne-based no-till systems for some soil conditions, vegetable and tree planting systems. The killing action of the Yeomans Keyline Plow shank is at once a setback when used by itself but a blessing if you want to establish seeds and other plants into existing pastures and not set back landscape function as a result.

We’re also looking to design a tow-hitch assembly so that the #KeylineSuperPlow can be easily transported by road vehicles from site to site. This same assembly would also allow us to use an ATV or 4WD to sow crops (without the Yeomans Keyline Plow shanks).

We’ll be designing a 3PL and trailing frame for the seedbox and double disc openers — again so producers can have a simple and low cost alternative to what’s on the market otherwise. We imagine that this kind of unit could be built for around AUD$10,000 (6 discs and 2m wide) and $14,000 for a 8 disc/3m wide machine.

Want to build your own #KeylineSuperPlow ?

- Ground-driven Seedbox Assembly (seedbox, mounts, drive, hoses and boots) – 2.0m wide – AUD$3500-4500

- Various Yeomans Keyline Plow Parts (3SB frame, 3 x 26″ shanks, depth wheels & coulter disc assemblies) – AUD$6000

- John Shearer Double Disc Openers OR Acra Double Disc Direct Drills (x 6) – AUD$6600

- RHS tubing, bolts and welding supplies – AUD$500

Total Funds Required – AUD$16,000-$17,000

If we add to this a small seedbox or 12V air-seeder along with a 12V liquids tank then that would add another $3000-$4000 — second hand parts would be cheaper.

Get the components from the following suppliers:

- Ground-driven Seedbox Assembly (seedbox, mounts, drive, hoses and boots) – Fix Engineering (AU)

- Ground-driven Seedboxes & Air Seeders – Farm Tech & Hatzenbichler (AU & Europe)

- Yeomans Keyline Plow – Yeomans Plow Co. (AU)

- John Shearer Double Disc Opener – John Shearer (AU)

- Acradrill ADU Units – Shield Agricultural Equipment (USA)

- RHS tubing, bolts and welding supplies – locally available

What a fantastic post! Thank you. A quick question?

I have a small farm and have a Yeomans Plow and crumble roller and have started to utilsie the plow ( on contour) with seed boxes (yeomans) to seed a combination of pasture, pasture herbs (chickory), plaintain and white clover. I have had some sucess; however, I assume it is a hit and miss in seed delivery to ensure seeds are droped at the right depth, location etc. I read the article above and was hoping to get some clarification of the following comments below. Is the “killing action of the Yeoman plow” comment highlight the stand alone action of the tynes damage the soil biology? however, when used in unison with seeding at the same time mitigates the damage caused by tilling. Hope that made sense?

Just wanted to understand and confirm if Yeomans Sub Soil plowing is still considered to be a good practice?

“The killing action of the Yeomans Keyline Plow shank is at once a setback when used by itself but a blessing if you want to establish seeds and other plants into existing pastures and not set back landscape function as a result.

Thank you, Paul

Firstly my apologies for overlooking your post Paul — we don’t get many comments and the notifications get lost in the daily pile sometimes.

The way I see it there has to be a bit of disturbance in order to create the germination conditions for what you’re sowing, which in ecological terms are relatively low succession plants. Do we kill/set back some soil biology/plant flora in the process? Absolutely and clearly our objective is to do that whilst creating the conditions for a many more to replace them as an outcome of this process.

How much soil biology gets killed as a result of plowing depends on a number of factors (and this is based on my guess and field observation not any science OK!). 1. Soil moisture content and temperature 2. Temperature and climate conditions (cloudy, rain following) 3. Irrigation timing 3. Plow speed 4. Surface disturbance and rip aperture (both of which are mitigated by the crumple roller).

I’m not a fan of the Yeomans seed boxes — they are very effective at loosing a lot of seed and are especially not great if you make seed mixes.

I hope this answers some of your questions.

Cheers,

Darren

Excellent summary of some innovative work, Darren. I would be interested in seeing how this could integrate tree planting. Are you currently still using tillage for large scale tree planting?

Thanks Jordan, you will see that the entire concept was born out of our tree planting contracting business from the mid-1990’s.

If you refer to the diagrams listed in 2006/7 you’ll see that we looked to integrate tree planting machines onto the Yeomans Plow. We actually did this in the late 90’s with a modified Holland Mechanical Transplanter (finger type) and V93 Hikos but I don’t have any photos. We also ran a Sfoggia cup transplanter behind the Yeomans quite successfully and that I do have some photos of though we were planting flats of herbs and forage shrubs directly. The great thing about the Yeomans SB frame is that its designed to mount other 3PL implements behind along with operate their PTO if necessary too. Allan Yeomans designed this so that farmers could attached Lely Roterra’s to the back of a Keyline Plow to do one pass ‘soil renovation’ — i.e. subsoiling, non-inversion surface disturbance and sowing (with the seedbox attached to the Roterra).

We’ve scaled back on our contracting business almost to nothing these days Jordan. That will change in the coming years however for now we’re concentrating on other things. However we do have a couple of pet projects that we’re doing some trials on currently where these lower tillage methods are being trialled. I don’t think that we’ll need to use a powered tiller again as a result though we need to complete more testing to be sure.

Thanks,

Darren

Is there anywhere that I can download the CAD files?

Regards

Peter

Pingback: La permaculture selon Bill Mollison - Les Dossiers de Micro & Macro