Regrarians’ are working with a number of clients across Australia and the USA who have, or are planning small-medium scale, and in some cases, mobile livestock processing units.

We are working with the likes of Tom Duncan (http://www.homeecology.net/), an old friend and colleague who among other things trained and worked extensively with the late, great Dr. George Chan.

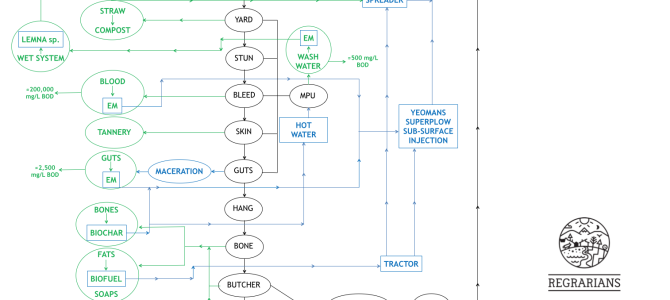

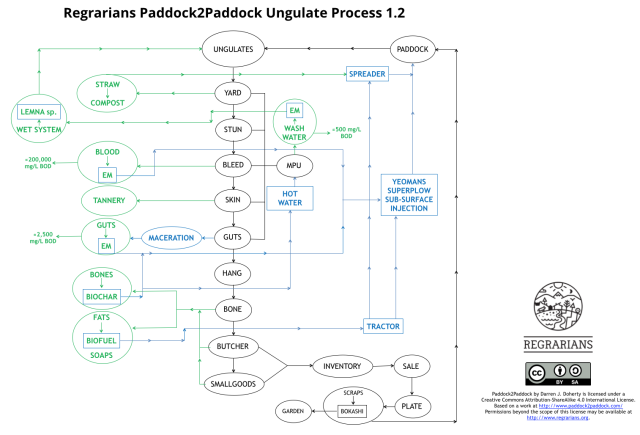

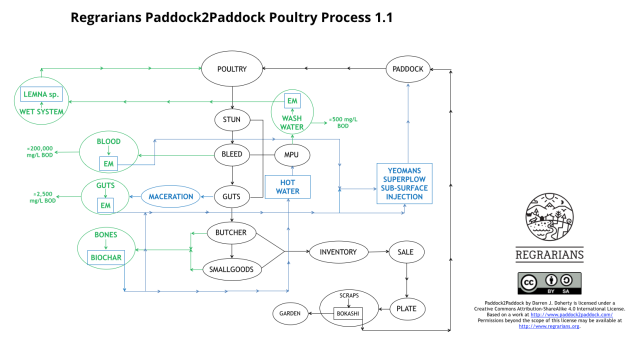

Regrarians’ Darren J. Doherty has developed what we’re calling the ‘Paddock2Paddock’ process. This provides the prospect for these small–medium scale processing outfits to include modular waste separation and processing using effective micro-organisms.

We are looking having some cues from people out there as to any instances where you know of the following items have been processed, how this took place, what was the resulting BOD of these outputs, what the end product was used for, and at what rates was it applied:

• Blood

• Viscera

• Feathers

• ‘Depleted’ wash down water (i.e. wash down water that does not include separated wastes such as blood, viscera and other solids)

In order to best provide development opportunities for ‘entrepreneurial nutrient cycling engines‘, processors and producers, the process that Regrarians develops, with the assistance of others, will be made available to the public as an open source process under the Creative Commons ‘Attribution Share-Alike’ licence.

I believe in NSW you can compost the render components if you have the space.

Takes about 6 months for a cubic meter of material to break down in 2 meters of carbon material like wood chips